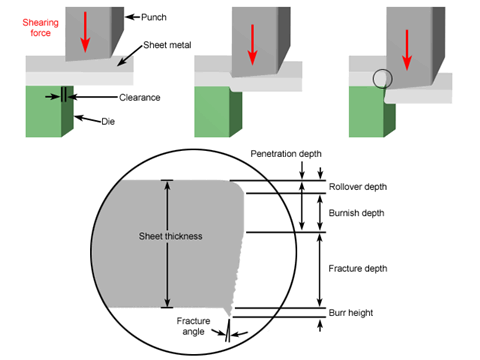

Cutting processes are those in which a piece of sheet metal is separated by applying a great enough force to caused the material to fail. The most common cutting processes are performed by applying a shearing force, and are therefore sometimes referred to as shearing processes. When a great enough shearing force is applied, the shear stress in the material will exceed the ultimate shear strength and the material will fail and separate at the cut location. This shearing force is applied by two tools, one above and one below the sheet. Whether these tools are a punch and die or upper and lower blades, the tool above the sheet delivers a quick downward blow to the sheet metal that rests over the lower tool. A small clearance is present between the edges of the upper and lower tools, which facilitates the fracture of the material. The size of this clearance is typically 2-10% of the material thickness and depends upon several factors, such as the specific shearing process, material, and sheet thickness.

The effects of shearing on the material change as the cut progresses and are visible on the edge of the sheared material. When the punch or blade impacts the sheet, the clearance between the tools allows the sheet to plastically deform and “rollover” the edge. As the tool penetrates the sheet further, the shearing results in a vertical burnished zone of material. Finally, the shear stress is too great and the material fractures at an angle with a small burr formed at the edge. The height of each of these portions of the cut depends on several factors, including the sharpness of the tools and the clearance between the tools.

Sheared edge

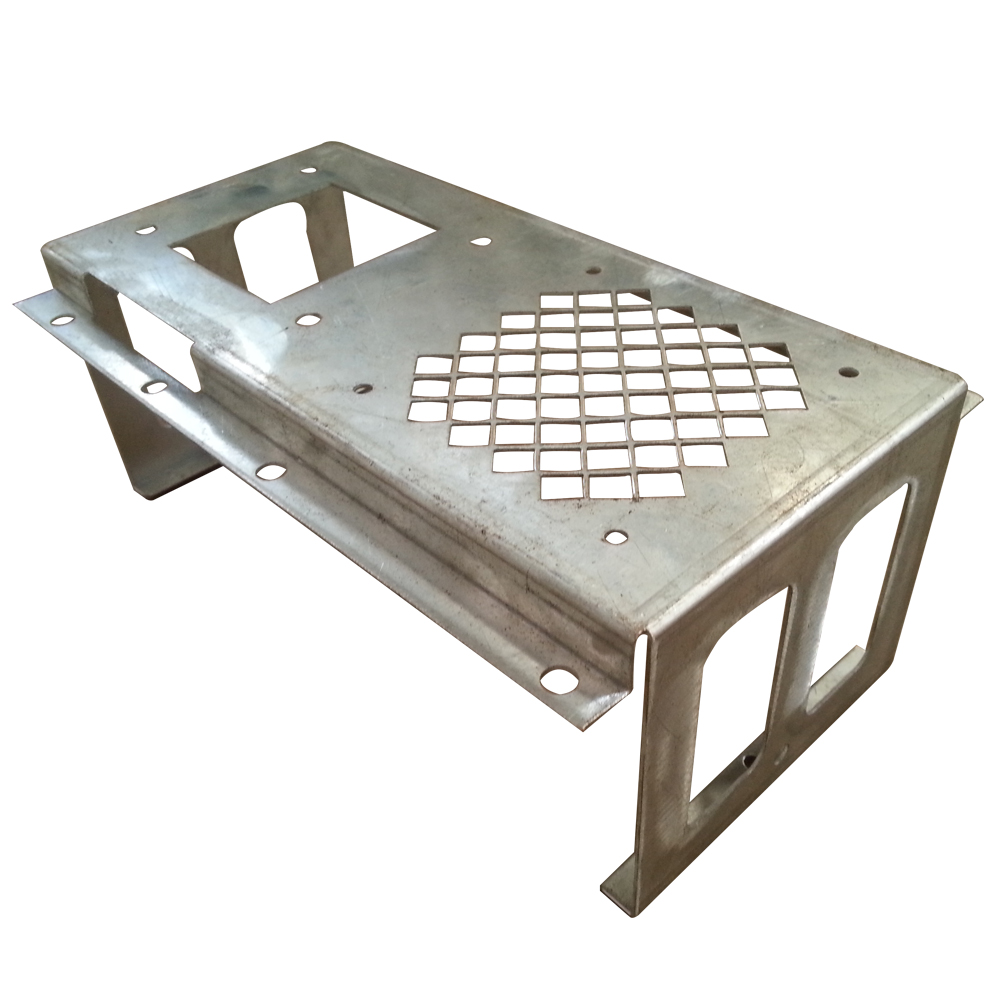

A variety of cutting processes that utilize shearing forces exist to separate or remove material from a piece of sheet stock in different ways. Each process is capable of forming a specific type of cut, some with an open path to separate a portion of material and some with a closed path to cutout and remove that material. By using many of these processes together, sheet metal parts can be fabricated with cutouts and profiles of any 2D geometry. Such cutting processes include the following:

- Shearing – Separating material into two parts

- Blanking – Removing material to use for parts

- Conventional blanking

- Fine blanking

- Punching – Removing material as scrap

- Piercing

- Slotting

- Perforating

- Notching

- Nibbling

- Lancing

- Slitting

- Parting

- Cutoff

- Trimming

- Shaving

- Dinking

近期评论