WELDING

Welding is a process in fabrication that conjoins materials, usually metals, via coalescence. It mildly melts the parts that are being welded and adds filler which turns to molten material to forma bond between the parts. Moreover, welding is one of the most critical operations in fabrication of sheet steel fabrication of assemblies. To some extent the strength of the assemblies depend on the quality of welding. Therefore, we take utmost care in welding operation.

There are seven different types of welding in the industry, some being more common than others. These seven types include:

- Spot welding:

This type of welding bonds materials from 3mm up to 12.5mm in thickness. Common industries for this type of welding includes automotive, and industries where sheet metal is being fabricated.

- Oxyfuel welding:

It involves combustion of acetylene in oxygen to create a flame temperature of about 5600°F. The flame melts the base metals and also the filler metal, and then quickly cools.

- Shielded metal arc welding (SMAW) aka stick arc welding:

This process uses an enclosed electrode, or a stick, to melt materials together. This is a more common type of welding.

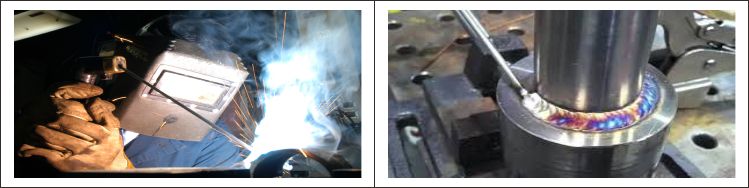

- TIG welding (Tungsten inert gas welding):

It also known as tungsten inert gas welding, uses Argon and Helium gases in processing. This form of welding is mostly used in industries where high detail and delicate parts are involved. TIG welding is also a good choice when there are many welding positions required. The Argon and Helium are used to shield the puddle instead of flux. This method is very versatile.

- MIG welding (Metal inert gas welding):

MIG welding stands for metal inert gas. In this process, a spool of wire is fed through a tip in the MIG gun. When the trigger is pulled,the tip melts the wire and forms a weld puddle. This process of welding works best on thin metals including stainless mild steel and aluminum, and is a very popular form of welding.

- Submerged arc welding:

This type is mostly used in thicker, heavier applications where you need a large deposit of filler material.

- Plasma-arc welding

Plasma-Arc welding is similar to TIG except that this process is great for very delicate applications in extremely thin metals.